Making of the 26" Beetle Stanley Chan |

|

A Bit of History Back in the early 2000, I was getting interest in acquiring a small r/c sailplane with wing span around 26". Apart from its small size, my other requirements are; it must have good aerobatics capability and be able to carve the airspace with speed in moderate to strong wind condition, it must be reasonably floaty when the wind is light, and it must be durable for landing on difficult terrain. These requirements are necessarily, as I would like to take the plane with me on hiking/soaring trips along various mountain ranges in the east coast of Hong Kong. After intensively searching for a while, I ended up ordering a 34" foamy B2 stealth bomber from GWS. I soon regretted for this move with disappointment of its aerobatics capability and durability. The next plane I felt interest in is 27" Switchblade from CSD. It is a conventional design with cruciform tail, bagged glass-clothed wing and fiber fuse. Although this plane satisfies me on the aerobatics side, it requires strong wind to maintain its capability and is pretty easy to break on landing. Most of my soaring trips ended up with just carrying this plane up and down the hill with no soaring, because there were insufficient wind to fly it. The experience I gained from these planes, however, is valuable. I strongly believe that, for a plane of that small, it must be tailless and with no fuselage so that the wing has minimum load to carry – a flying wing design! I also believe that, for aerobatics efficiency, the wing should not be swept back as in the case of Zagi or a delta. So the search continued without success. Then, I was thinking to design and make the plane myself. For the reason of durability, EPP foam was my initial choice, however, EPP is difficult to find in Hong Kong and also I need a good foam cutter to cut the wing profile, which is expensive and not readily available. So I put off the project for a while until one day on December, 2001 when I saw a fellow pilot who test-flown his homebuilt delta wing. His construction technique for building the delta is somewhat innovative. He cut two delta shape sheets of Coroplast; a kind of material that is made of plastic with two thin sheets placed in parallel with hollow strips connecting between them, and he sticks the two Coroplast sheets together by ordinary tape, between them put the servos, receiver and battery. The top sheet is forced to have a curvature as similar to a cambered airfoil while the bottom is flat. This construction technique, although primitive, is really making sense; the Coroplast material is light, can be blended and strong enough for small plane! The cost of Coroplast sheet is cheap too, we can buy a 26"x20" sheet for just 2 US dollars in Hong Kong! His delta wing although was made very rough - even the wing platform is not very symmetric due to uneven blending forces, it is marginally flyable! So I immediately came back to my original design and started the construction – then Beetle was born!

|

|

Design of Beetle My first requirement of the design is somewhat stubborn, insisting that the plane is a flying wing with no sweep back and no fuse. I knew that, from an example of JW, its wing is a non swept wing (old version) and its aerobatics skill is good, however, it is relatively heavy for light wind soaring as it has the load burden of the fuse. I also believe that two yaw-stabilizing fins on the wingtips as in the case of most flying wings such as Zagi and Jazz are unnecessary, it will severely affect the roll rate of the plane. So for a single fin, it must be located behind the centre point of the wing. A non-swept wing with no fuse and a centered fin? This vision of design was wondering around and later confirmed when I saw the shape of Bluto from NCFM, sailplane of this shape really flies! With a non-swept wing and reflex airfoil, the CG must locate in front of the neutral (c/4) point, there is no way you can balance the plane if there is no head extended out in the front. JW did this with a fuse, which is of no use aerodynamically except for CG balancing. Bluto’s way of solving this problem is genius, it extends the wing section in front and keep the airfoil shape! So heavy ballast can be put in the extended section to balance the CG while the airfoil shape generates extra lift. In order to confirm my thought, I immediately started working on the geometry of the plane. As I intend to use Coroplast sheets to form the wing without worrying of cutting a precise foam core, I can use a more streamlined shape of the leading edges so that the neutral point is located as far back as possible. Therefore a smaller amount of ballast can be used to balance the CG, this results in less overall flying weight. I also choose to use a small extend front section so that the range of CG is wider. The outcome, surprisingly, is a bird-like shape (except the tail) as shown.

Next come the selection of airfoil for the wing. From my experience in airfoil, delta wing must use a reflex airfoil, as there is no tail to stabilize pitching. My design objective is to have a fast, slippery plane, however, there is no reflex airfoil that really satisfies my demand. Therefore, I look at the cambered airfoil such as HN1038, which is one of the most slippery airfoil I have experience with. Because of the construction method I use, two Coroplast sheets will join together in the trailing edge, I can make a small reflex in the trailing edge by cutting out part of the bottom sheet near the trailing edge. So the airfoil I chose, in a strict sense, is a modified HN1038.

|

|

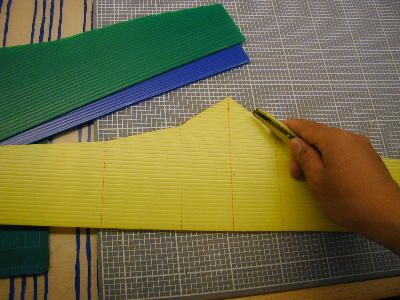

Construction of Beetle Step 1 – Prepare the wing sheets Cut the top and bottle wing skins from Coroplast sheets according to the plan shown (the aileron section is not included and will be added later). Coroplast sheet of dimension 26"x20" is available from many office accessory stores in Hong Kong for just HK$15. Note that the direction of fiber strips in the cut Coroplast sheets must be parallel to the wing trailing edge in order to provide longitudinal strength to the wing. You may cut the top sheet slightly bigger than the bottom sheet as the top sheet will have a bigger curvature in forming the wing. Choose to use different colours for the top and bottom sheets, as the plane will be easier to spot during invert flight or aerobatics. |

|

|

|

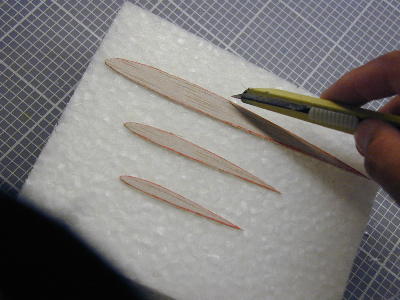

Step 2 – Prepare the airfoil ribs Prepare three balsa airfoil templates with difference sizes from the HN1038 airfoil database, http://www.habebert.de/profile/hn1038.pdf. The lengths of the three templates are 5.7", 3.3" and 2.5" respectively. To do this, you need to reduce the airfoil drawing obtained from the database to the corresponding sizes and print them out on paper. Scissors the airfoil printout, then stick it to a balsa sheet and cut the balsa templates accordingly. Use the balsa templates as guide to cut the foam ribs of 0.5" in width from scraped EPP foam (or other type of form) left over from previous model building projects. You need 5 foam ribs, one 5.7" rib for the centre section, two 3.3" ribs for the middle sections and two 2.5" ribs for the wing tip sections. |

|

|

|

Step 3 – making the wing Temporally tape two wing sheets together on the trailing edge using masking tape. Lay the bottom wing sheet on the table and use a small amount of Epoxy to hold the foam ribs into positions; the 5.7" rib goes to the centre, the 3.3" ribs are fixed at 5" from the wing centre, and the 2.5" ribs are fixed at 1.8" from the wing tip. Make sure that the ribs are aligned properly from the leading and trailing edges of the wing sheet. Then paste the 30 minute Epoxy to the top and bottom of the foam ribs. Apply reasonably force to press the two wing sheets together and tape them in place using masking tape. Visually inspect the wing profile to avoid any irregular surface and warp. You may apply a small dihedral if you like, however, the Beetle can fly very well without dihedral. Let the Epoxy to dry for an hour. |

|

|

|

Step 4 – tapping and trimming the wing sheets Remove the masking tape in the leading edge, round off the leading edge of wing tips by using a sharp knife. Make sure both wing tips are symmetrical. Use the 1.88" strong tape (with fiber), such as Nikko tape, to tape the leading edges of the top and bottom sheets together, apply force to press the leading edge so that a sharp and straight edge is obtained. |

|

|

|

| Cut off the outer layer of the Coroplast of the bottom sheet to about 0.5" from the trailing edge (see the picture below). This will create a small reflex in airfoil after the top and bottom sheets are taped together at the trailing edge. Use the 1.88" strong fibre tape to tape the top and bottom sheet together at the trailing edge. Make sure that the edge is straight and apply force to squeeze the edge as thin as possible. Visually inspect the airfoil again for irregular shapes and warps. | |

|

|

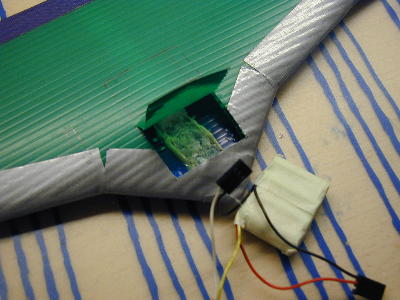

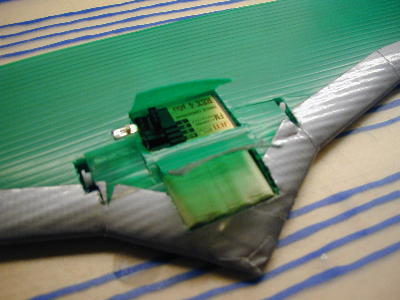

Step 5 (radio installation) Cut from the top of the wing sheet to make apartments for the battery and receiver according to the plan. Move the battery to as far front as possible as this will minimize the ballast used to balance the plane. I use a 4.8v 280mAh GP rechargeable battery pack and a 4-channel JETI miniature receiver. Extend the receiver’s antenna wire to the full wing span. I found that the fibre hollow strip inside the Coroplast sheet is useful as guide to make the antenna wire straight. Install and epoxy a servo to the each side of the receiver/battery pack and move them as far front as possible. Cut a small rectangular hole to allow the servo arm to extend out on the top of the wing, and make sure that the arm can move freely over its range of travel. You may also install a power on/off switch and a charging cable outlet. Use a 1.88" fibre tape (with different colour to the one used in tapping the wing sheets) to cover and protect the radio apartments. |

|

|

|

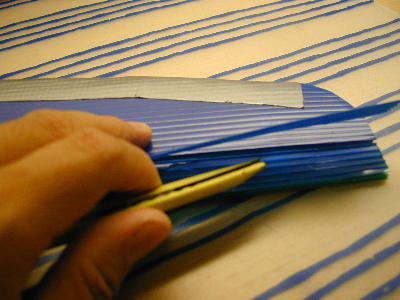

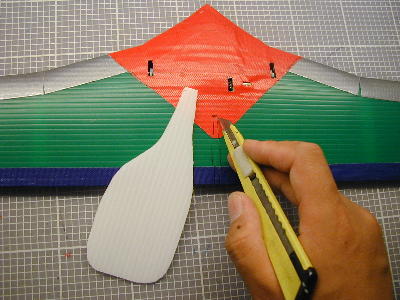

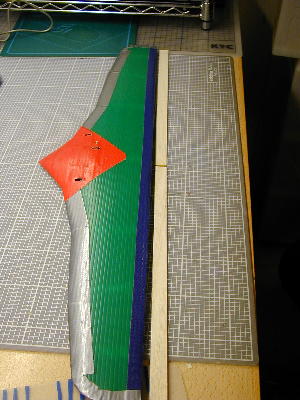

Step 6 – Install the tail fin and the ailerons Cut the tail fin according to the plan shown. Make sure the fibre strips in the Coroplast are parallel to the longer dimension of the fin as this will provide strength in case of blending in flight and on landing. Cut a ditch of 3mm wide and 2" long from the trailing edge in the top skin at the centre line for the fin to fit in. Don’t cut through the bottom skin of the wing. Trail fit the fin to the ditch and make sure that the fin is straight with no deviated angle from the centre line. Epoxy the fin in place. Make two ailerons of dimension 12.75"x0.625" from 2mm thick balsa sheet. Tape the aileron in place as shown in the plan using the Scotch tape. Make the control rods from 4.5" musical wires. Make a z-bench at both end of the wire. Epoxy a control horn to the aileron and link it to the servo horn with the rod. You can adjust the aileron neutral position by z-blending the music wire appropriately. |

|

|

|

|

|

Control Settings: Elevator both ailerons up/down +3mm/-3mm Turn right left aileron / right aileron -5mm/+5mm Turn left left aileron / right aileron +5mm/-5mm CG 3.625" from the trailing edge (you may need to install some ballast in the front head to achieve this)

|

|

Flying the Beetle On a cloudy day with occasional rain, I test flown my tiny Beetle in Clearwater Bay. The wind was moderate with average speed around 15km/hr. The pre-launch check for CG is straightforward and the plane doesn’t seem to have any bad tendency. I didn’t install a beeper on board so I was a bit hesitate to launch it on a wet day particularly in Clearwater Bay as the pick up is extremely difficult, don’t mention my ability to spot the tiny plane in the jungle of wet bushes! Anyway, the first launch was somehow embarrassing as the plane was shooting up after launched and heading back towards the road hitting a fellow pilot on its way. Fortunately, no body was hurt and no damage to the plane. After the adjustment to the neutral positions of the ailerons, I launched it again, this time was uneventful and the plane just glided steadily down the slope and picked up its speed on the way. A few turns and fly-passes were carried out, the plane was very responsive to the control inputs and it was apparently fast! Invert flight, inside/outside loops and rolls can be performed with ease. Surprisingly, this little plane can pick up speed fast after the turn. Subsequent tests on lighter wind conditions confirmed that Beetle is flyable at about 5 km/hr. In strong wind condition with some ballast installed, this little plane is really a fast aerobatics devil. |

|

|

|

| For more pictures and movies of Beetle, please see beetle | |

| You may also download the construction manual at Beetle_Manual.pdf | |

| Recent Updates I have since developed several versions of Beetles with different sizes and wing profiles. So far the 39" Beetle with elliptic wing is the one that I love most. Speed, good aerobatics and easy to carry are the contributing factors. You may download the plan for the 39" and 52" Beetle here Beetle39.pdf, Beetle52.pdf |

|

|

|

|

|

|